Cutting Optimization Pro 6 Crack + Serial Key Full Version Free Download

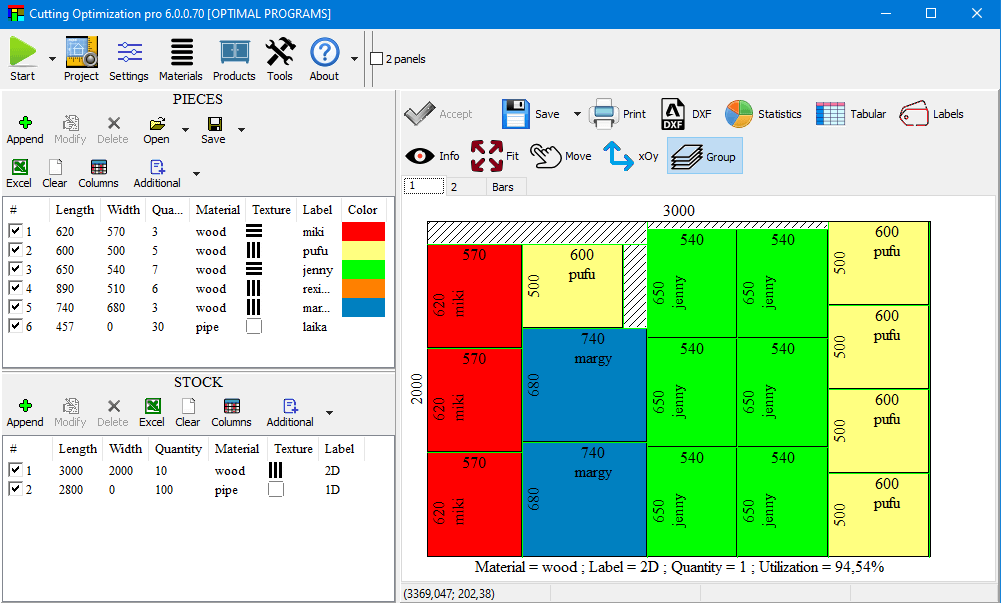

Cutting Optimization Pro Crack is cutting software that helps you create optimal cutting designs for one-dimensional (1D) and two-dimensional (2D) parts. The software also allows you to define and modify complex products such as tables, desks, cabinets and shelves.

Cutting Optimization Pro allows you to cut rectangular panels from glass, wood, metal, plastic or other materials used in industrial applications. Optimization Pro can also be used as cutting software for straight parts such as bars, pipes, tubes, steel bars, metal profiles, extrusions, tubes, straight wood panels, etc. and other materials.

Cutting Optimization Pro allows you to define and edit complex products such as tables, desks, cabinets, cabinets and shelves. It can be used to cut rectangular panels made of glass, wood, metal, plastic or other materials used in industrial applications. Cutting Optimization Pro can also be used as cutting software for straight parts such as bars, tubes, tubes, steel bars, metal profiles, extrusions, tubes, straight wooden boards, etc.

Features include 1D and 2D optimization in the same cutting program, guillotine optimization, non-guillotine (nested) optimization, multi-stage guillotine, any number of parts in stock and on demand, any measurement criteria, adjustable optimization levels, maximum cutting length, adjustable limits for fragile parts, graphic display of black and white or color images and text mode of the results obtained, vertical printing of labels and borders, CNC display of cuts in the text format used by the machine, automatic calculation tools that they allow you to adapt the dimensions of the parts to the external dimensions of the products so that you can export the data in very common formats. All panels and table columns can be resized.

Cutting Optimization Pro is detailed cutting software that enables optimal cutting design for 1D and 2D dimensional parts. The software includes tools that allow users to define and manage complex products such as tables, desks, cabinets, cabinets and shelves. Ideal for cutting rectangular glass, wood, metal and plastic panels. It is also used for cutting other materials commonly used in industrial applications.

An important feature of this application is the measurement accuracy. This allows for precise and precise cuts. All cuts are displayed in text format so they can be used on CNC machines. CNC machines are used to cut and move materials as programmed in the software. With Cutting Optimization Pro you can generate optimizations for 2D and 1D materials. All cuts are presented as JPEG images that can be saved to disk or even printed. Follow the steps below to know how to download Cutting Optimization Pro for free on your PC.

Cutting Optimization Pro can find the optimal cutting size for 1D and 2D parts. The guillotine optimization feature creates cutting patterns that only require moving the cutting tool from one side of the part to the other. Controlling the direction of the grain helps optimize the woodcut. You can use parameters to specify whether a part can be rotated or locked. There are many other optimization features that can help with cropping.

Cutting Optimization Pro Crack is a great software that allows you to design plans when you need to cut different types of materials. The automatic tools calculate the dimensions of the piece, be it wood, glass or metal, and design the ideal cutting pattern based on the external dimensions, working with both 1D and 2D optimization.

Features & Highlights:

- Get 1D and 2D optimization in the same cutting program.

- Guillotine and non-guillotine (nested) optimization.

- Multi-stage guillotine: each cut in one stage is perpendicular to the cut in the previous stage. User can set the number of phases and cutting direction of the first phase.

- There is no limit to the number of parts to optimize and you can add any number of parts to STOCK and DEMAND.

- Use any metric.

- Adjustable cutting blade resistance, optimization level and limitations on fragile parts.

- Automatic tool that calculates the size of a part based on the external dimension of the product.

- Export your data in multiple standard formats (Word, Excel, HTML, CSV, XML files).

- Define the type of material (glass, wood, slats, etc.) with which the software will work.

- 1D and 2D optimization in the same cutting program: The program can be used for 2D and 1D optimization.

- Guillotine optimization: the cut is made from one side of the material to the other. This function is very useful for glass, wood, thermal glass, etc.

- Optimization without guillotine (nesting): the cutting machine can follow the shape of the material. In this case, complex machines based on lasers or flame blades are required.

- Multi-stage guillotine: each cut in one stage is perpendicular to the cut in the previous stage. User can set the number of phases and cutting direction of the first phase.

- Any number of pieces in STOCK and DEMAND: there are practically no limits to the number of pieces to optimize.

- Any metric: The way data is entered is common. You do not need to provide any metrics. Simply choose a metric in your head and enter all your data using only that metric.

- Partial entry. Pieces of 100.5 or 100 1/2 can be inserted. You can find more information about decimal input here.

- Adjustable cutting blade thickness: When cutting diamond glass, the cutting blade thickness is 0, but when working with wood or metal, a thicker saw blade is needed.

- Adjustable optimization level: You can set the number of projects generated before the solution is generated. If you don’t have much time or a suitable computer, you can set the optimization level to a lower level. This feature allows you to run your program on all types of computers, from 486 to the best processors available today.

- Maximum cutting length limit: You can specify the length that can be cut. This is useful for manual cuts.

- Adjustable Useful Waste: Any waste smaller than this size is considered rubbish (it will not be placed in the bin).

- Adjustable limits for fragile parts: no waste size is smaller than this parameter and no two parallel cuts are closer together. It is used to prevent damage to very small materials. Useful in the glass industry.

- Reduce dashboard waste and costs: Leverage the latest advances in artificial intelligence to reduce waste.

- Grain Direction Control: Helps optimize wood cutting. Parameters allow the user to specify whether the part can rotate or remain fixed.

- Automatic Scrap Management – Useful scraps are automatically added to your material inventory.

- Vertical label and border printing: streamline and simplify your design.

- Graphical representation of the results obtained in black and white or color images and in text mode: The results are displayed as images (black and white or color) or as text tables.

- Automatic image saving: Save all scanned 2D sheets as JPEG images with just one click. The program automatically adds numbers to images.

- Copy and paste from Excel. Simply select a few Excel columns and insert them into the demand or inventory grid.

- Group similar designs together – this will reduce the number of sheets printed. Displays the number of repetitions of each sheet.

- Sketchup Exporter: We offer a free plugin for Sketchup that allows you to export the component dimensions of your Sketchup model to files loaded by Cutting Optimization Pro. You can find the details here.

- Expand the sheet. This is useful if you have long rolls that can be enlarged for viewing.

- Print the received design on any printer.

- Print multiple designs on the same page: you can print 1, 2, 4 or 6 designs on the same paper.

- Printing repositories and custom requests: You can print the parts you want to optimize.

- Cuts are displayed in text format for use by CNC machines.

- Edge manipulation: The program manipulates the amount and type of material that adheres to the edges of the wood panel.

- Calculate/print the total cutting length.

- View table: table showing the cut pieces for each sheet.

- Ability to define complex products such as tables, desks, furniture, cabinets, bookcases, etc.

- Possibility of defining the type of material (glass, wood, slats) – For each material, a specific table is available to the user where the user can enter detailed information on the material.

- This is a tool that automatically calculates the size of parts based on the external dimensions of the product.

- Statistics on the current cut/layout: At the end of the optimization process, you can access the number of cuts, the definition of the cut (start and end points), the number of waste rectangles and number of waste rectangles (top coordinates). It will be like this. ). left corner and bottom right corner), the number of parts to use, the arrangement of the parts to use, the surface to use, …

- Save/Load Results: All results can be saved to a text file and loaded later.

- Create and print adhesive labels –

- Load data from .xml, .dbt (version 4 specific files), .xls (Excel files), and .csv (comma separated) files.

- Automatic order price calculation –

- Sort parts and inventory based on multiple criteria including length, width, quantity, type, rotation and labels.

- Maximize productivity and save time and money.

- Data can be exported to common formats such as Word, Excel, HTML, CSV (comma separated) and XML files.

- All tablespaces and columns can be resized to customize your workspace. The new location is automatically saved.

- Extremely fast response times: solutions are available within seconds.

- Native Win32 application. No dependencies required.

- Single file request. You can move a single file to a new computer and run it without installing it.

- It allows for very efficient writing. The EXE file weighs approximately 6 MB and the installation kit weighs just over 1 MB.

- Desktop application. You control your data. There is no risk of your data being lost in the event of a remote server failure. Applications can run smoothly even when the Internet is down.

- Multilingual user interface.

What’s New?

- This release may contain unspecified updates, improvements, or bug fixes.

- The “Save data and parameters” menu has been moved to the “Services” menu.

- Load data from Woody-CAD (furniture design program). Simply click on the prompt toolbar and select the WoodyCAD file type.

- Optimization results can be loaded or saved from a text file. Added new results menu | Save results and achievements | Upload the results.

- Improved data export/import in various formats. Introduced CSV (comma separated) and INI formats for exporting/importing requests and repositories. Table headers (including column names) are no longer exported or imported.

- Improved visualization of 2D results.

- Better optimization.

- A new type of optimization (multi-stage guillotine). Replaces the old two-stage optimization.

- Optimization settings have been redesigned.

- The help has been moved to HTML format.

- Online help.

- This is useful when some parts are very small and the information cannot be displayed well.

- Edge bands can be visualized as colored lines.

- New printing options.

- New interface options.

- Language options have been changed in Settings | tongue moved.

Cutting Optimization Pro Serial Key:

QAWSEDRFTGYHUJIKOKIJUYT5R4E3WASEDRFTY

YTR4E3WASEDRFTYU89IOIJUHYGTR4EW3SEDRFT

YGTFRDESWAZSDRFTY7U8IUYTRESDRFTY78UUYG

GTFRDESWAZSDRTY7U8IUHYT5R4E3WSEDRTYUH

System Requirements:

- System: Windows 7 / Vista / 7/8/10

- RAM: Minimum 512 MB.

- HHD space: 100 MB or more.

- Processor:2 MHz or faster.

How to Install Cutting Optimization Pro Crack?

- Download the software and run the installation file.

- Click “I Agree” to continue.

- Select the installation method and click “Next”.

- Change the installation folder and click “Next”.

- Select the components and click Install to start the installation.

- After setup is complete, click Close.

- Done! Enjoy it.